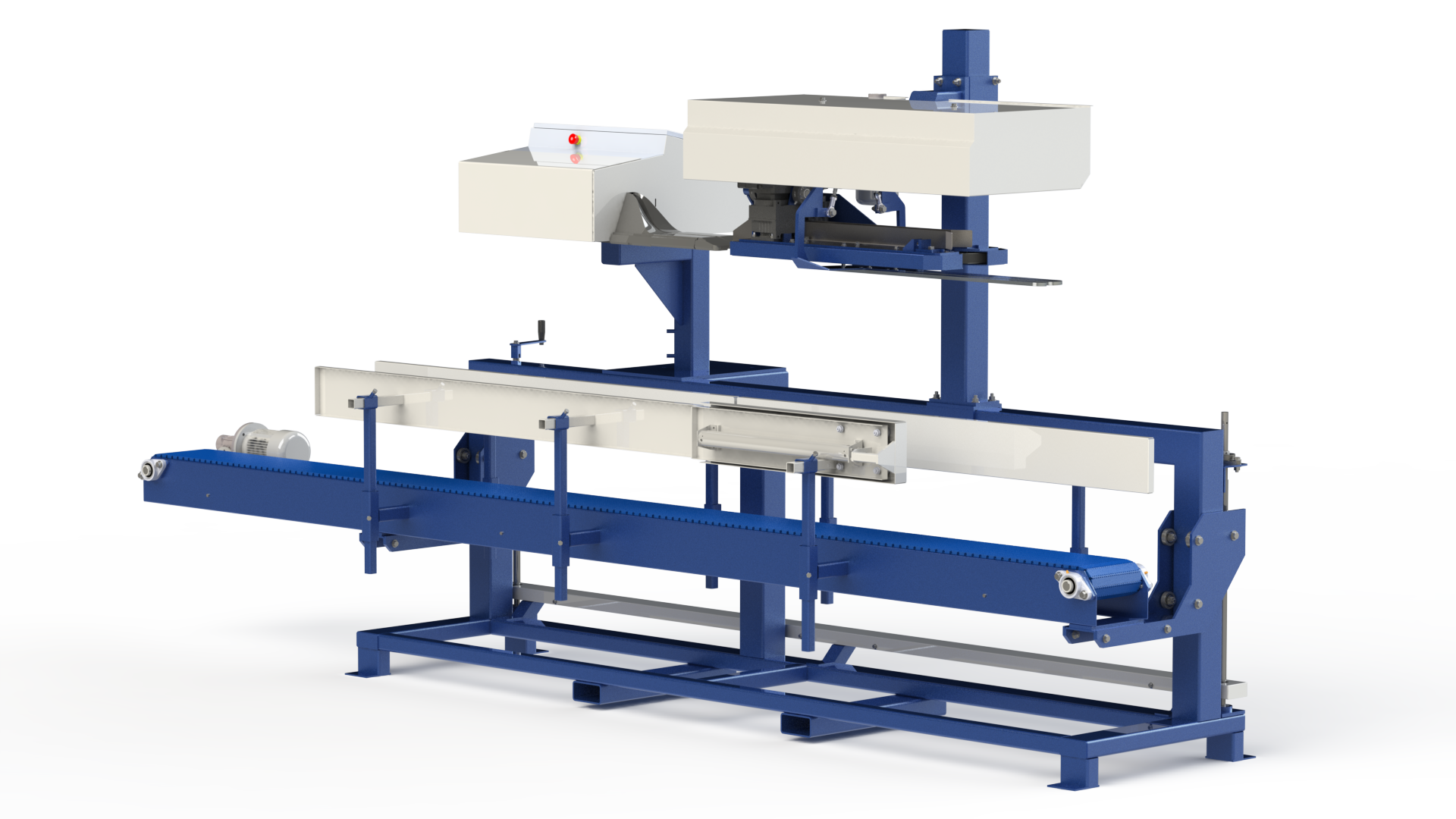

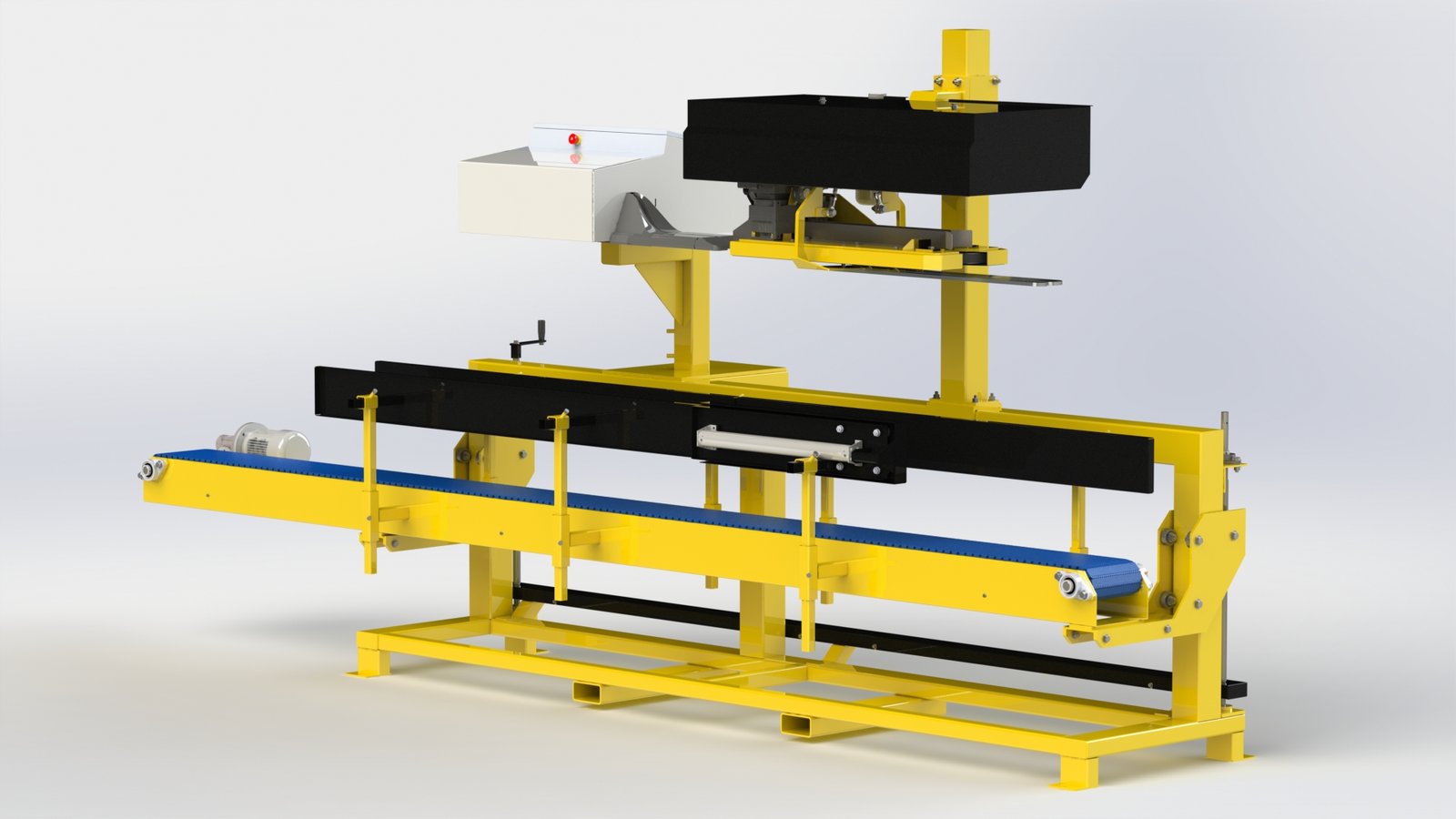

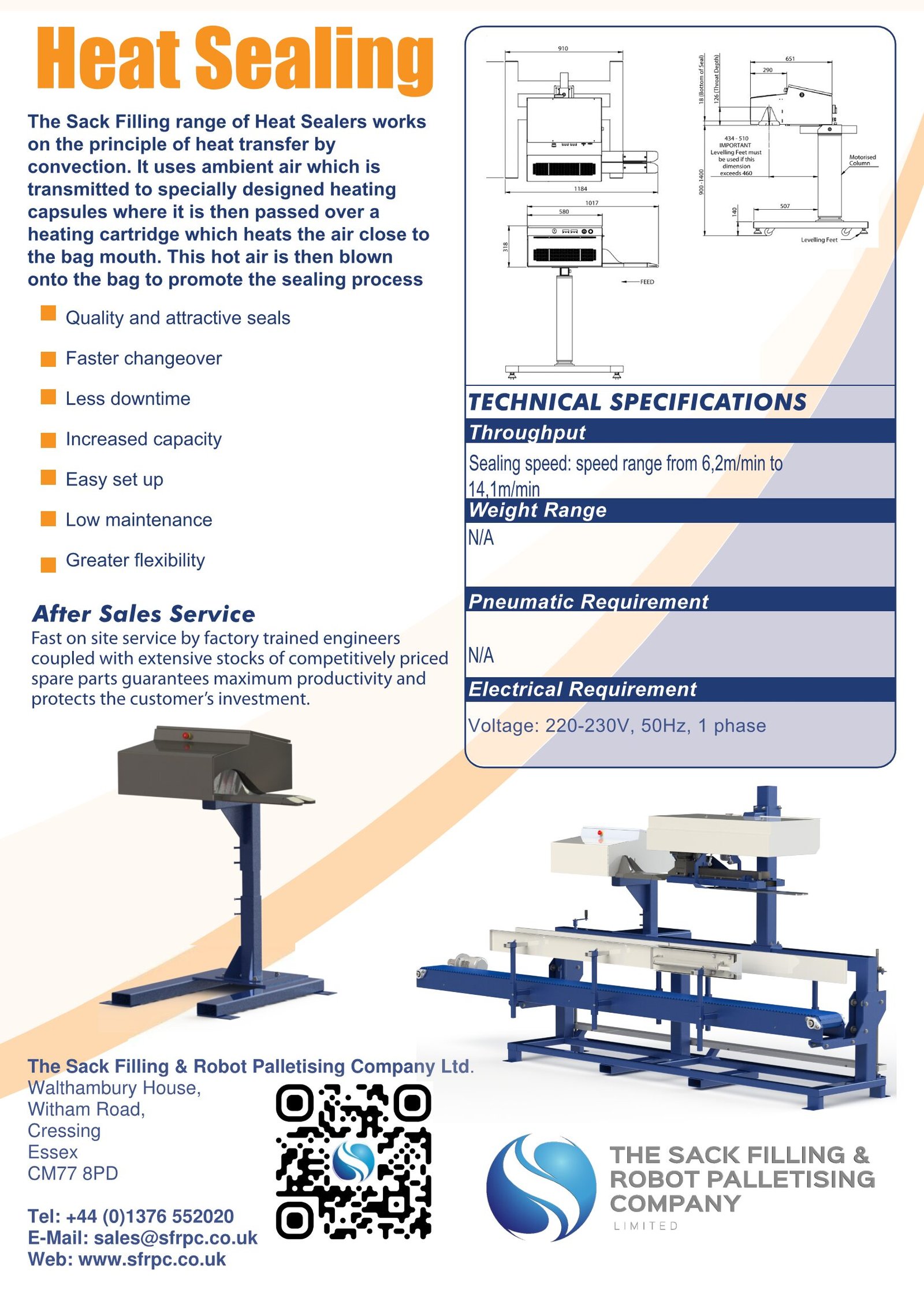

Heat Sealing

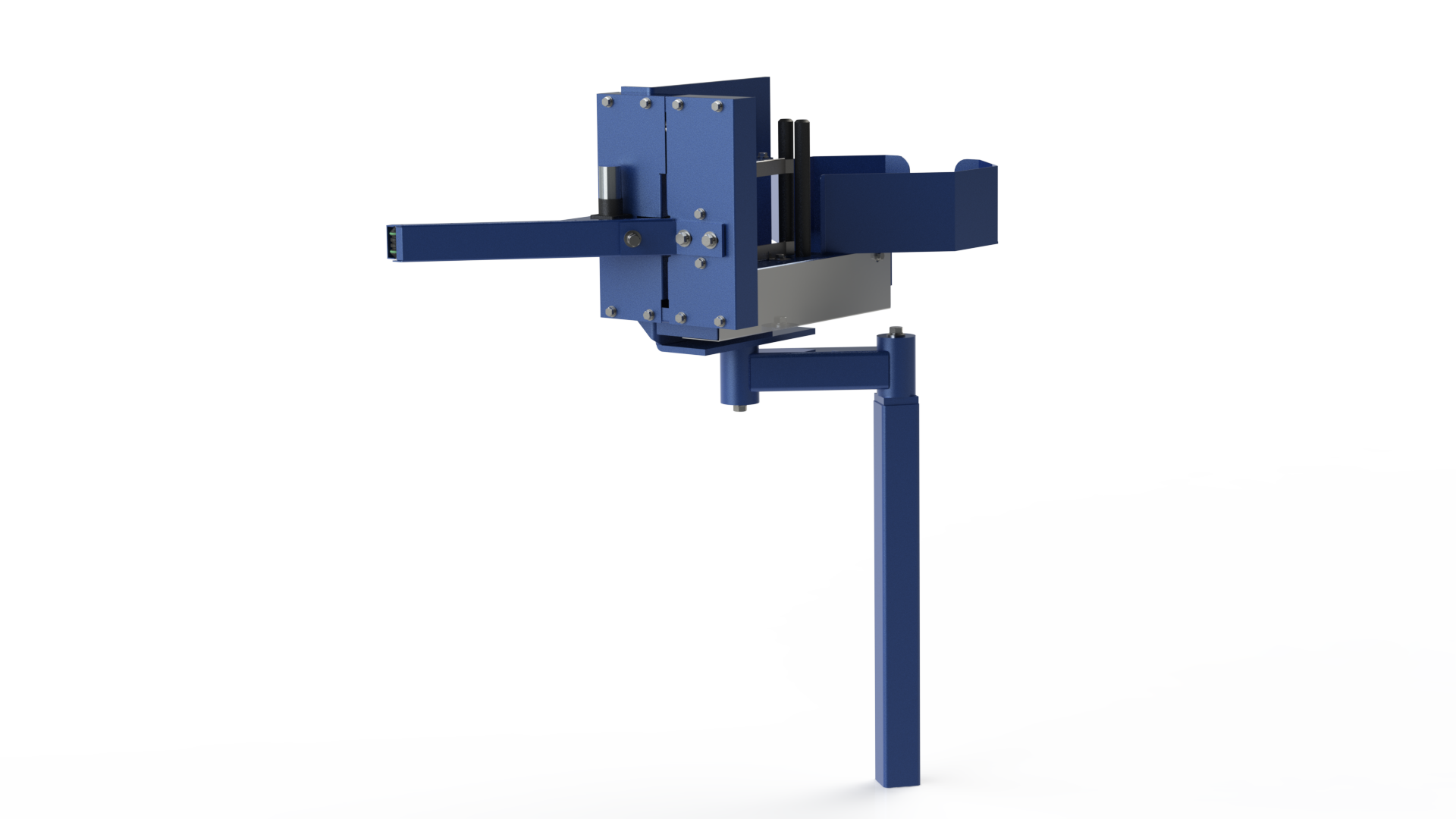

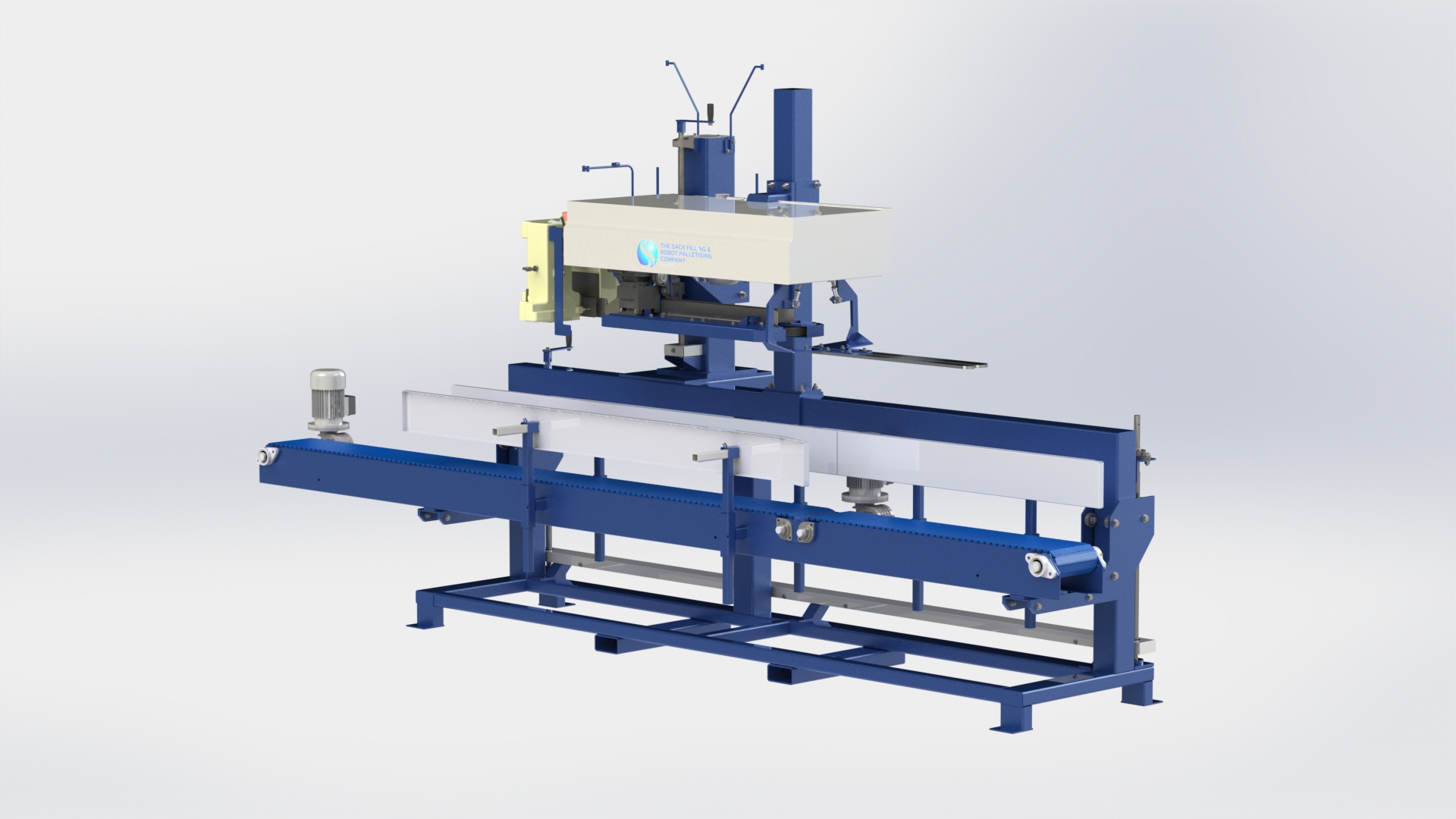

The Hot Air Sealer SH1000 uses the principle of heat transfer by convection. It uses ambient air which is transmitted to specially designed heating capsules where it is then passed over a heating cartridge which heats the air close to the bag mouth. This hot air is then blown onto the bag to promote the sealing process.

Contact about this product

Key Benefits

- Up to 14.1 meters per minute sealing speed as standard (up to 22.2 meters per minute on request)

- Stainless steel construction- ideal for food products.

- Optimized heater airflow for higher operating speeds and increased productivity.

- PID temperature control.

- Simple setup adjustment- fast product change over.

- Low profile infeed ensuring correct bag presentation.

- Can be used in conjunction with the M855 auto infeeder.

- Fully compatible with The Sack Filling Company’s range of Sack Top Control Systems.

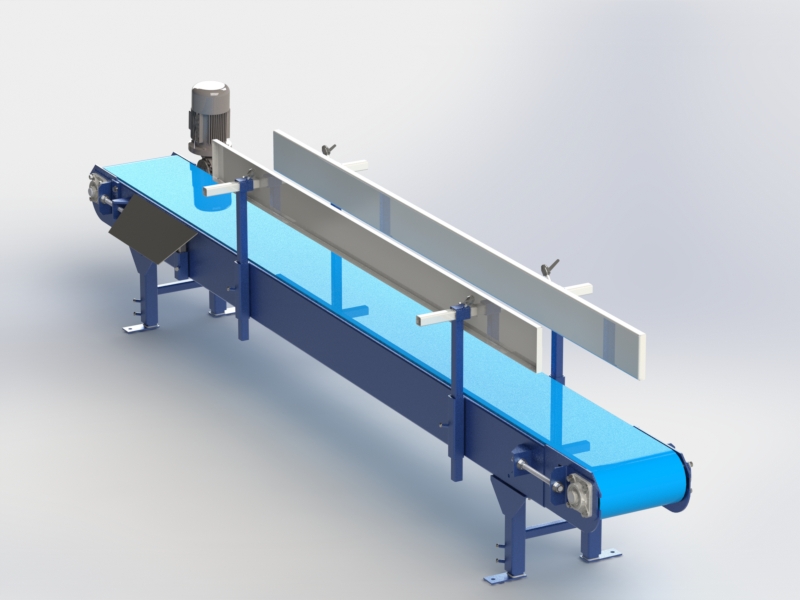

- Fully compatible with The Sack Filling Company’s range of conveyors systems.

Optional Extras

- Both L-R and R-L operation direction versions available.

- Motorized height adjuster

- Airevac to remove excess air from bag before full closure.

- ATEX approved versions available.

- Post-seal bag top cooler.