Supersealer SS2

The Supersealer SS2 Hot Air Sealers utilizes hot air to continuously seal a wide range of bag materials at high speed and efficiency.

The advanced airflow, sophisticated controls, and 316 stainless steel construction, ensures continuous uptime performance in all applications.

By using ambient air to seal the bag, there is no requirements for compressed air.

The Supersealer gives customers a low maintenance and an outstanding return on investment along with the many years of uptime the machine will have

Contact about this product

Key Benefits

- Hot Air Sealing Technology: Optimum seal quality at low maintenance.

- No Teflon bands.

- Variable Speed: Ease of matching conveyor speed for flexibility

- Closed Loop Temperature Control: Accurate and consistent sealing temperature

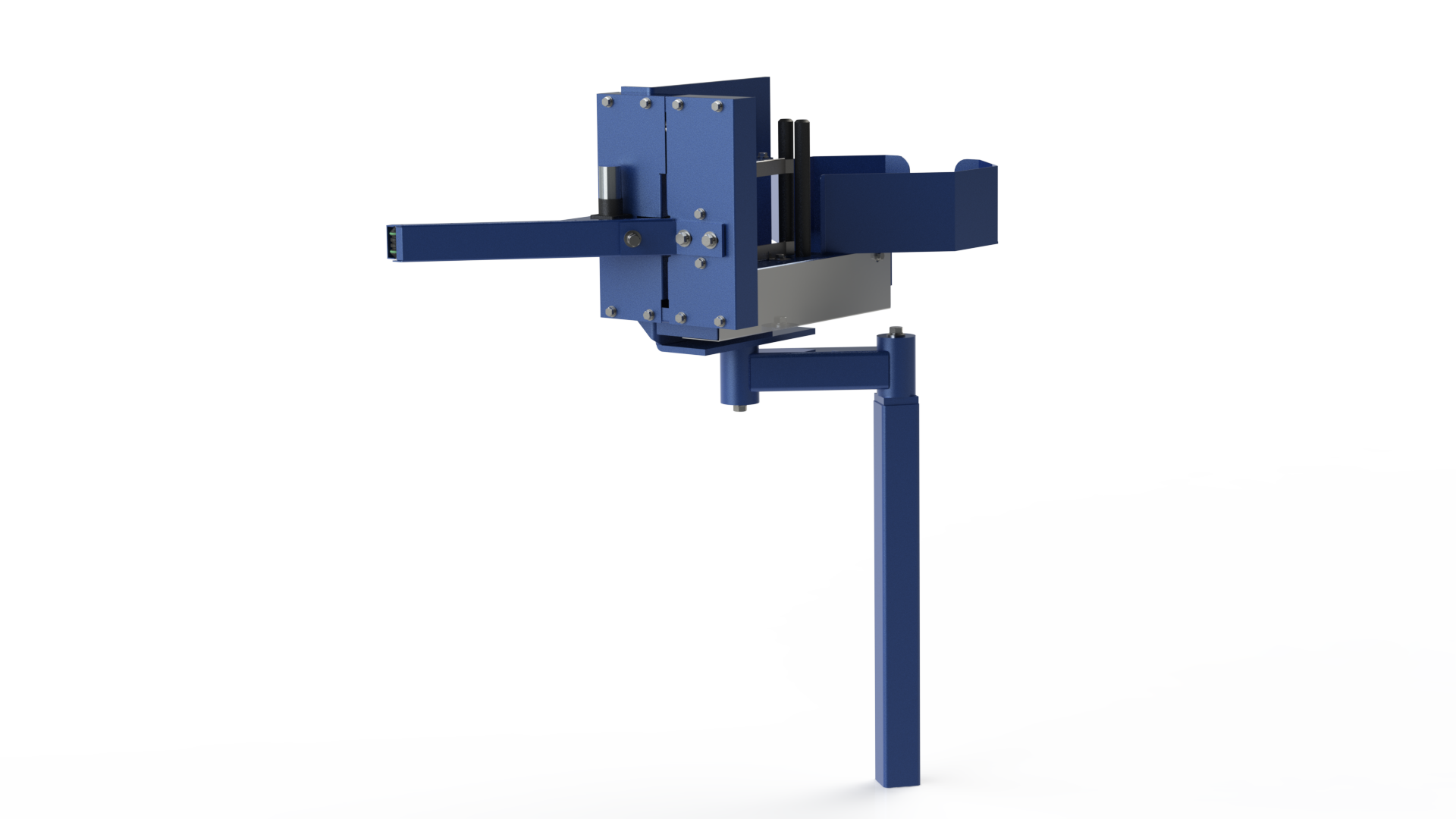

- Motorized Pedestal: Height adjustment with a button simplifies multiple bag size sealing runs

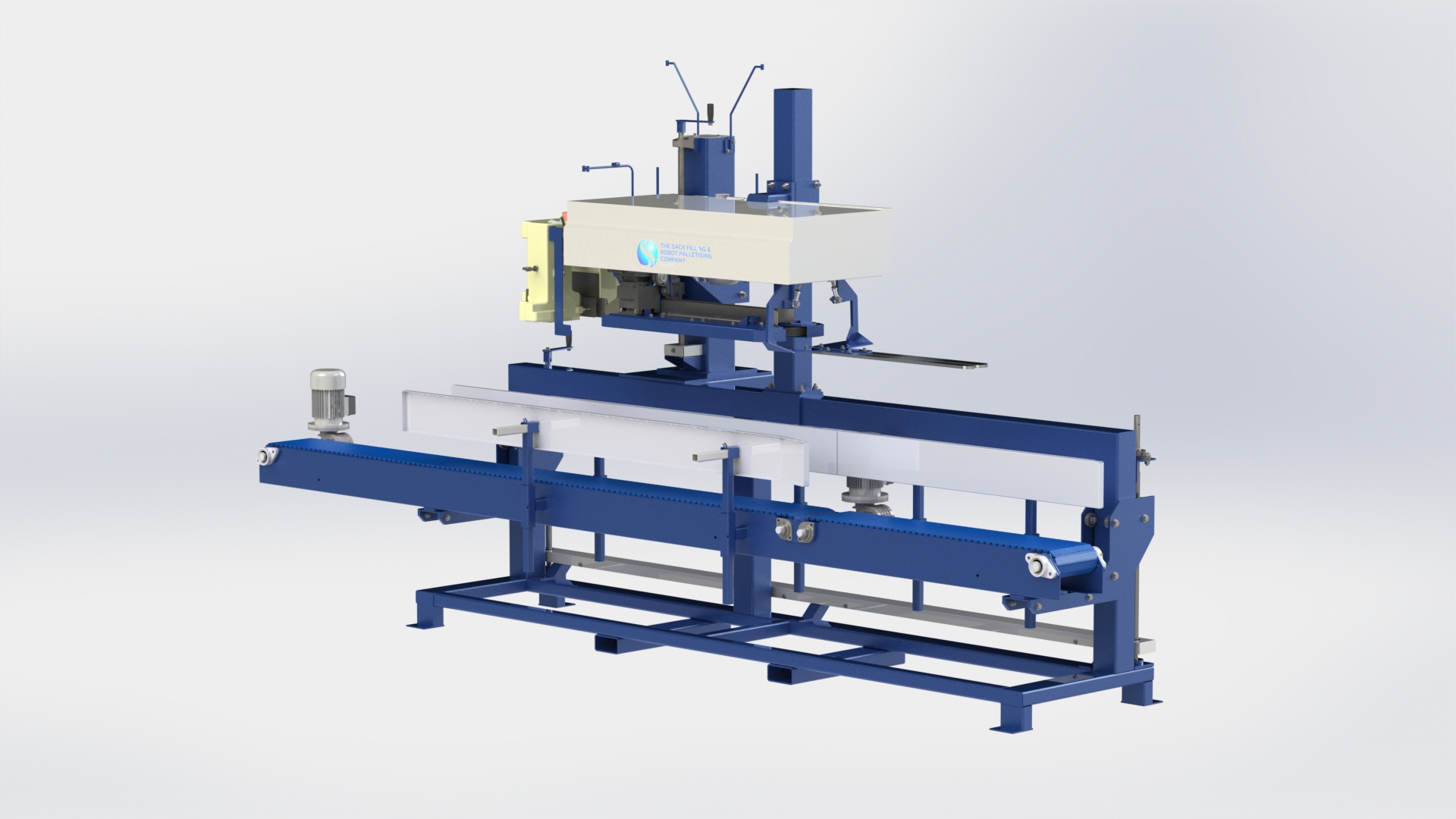

- Can be used in conjunction with the M855 auto infeeder.

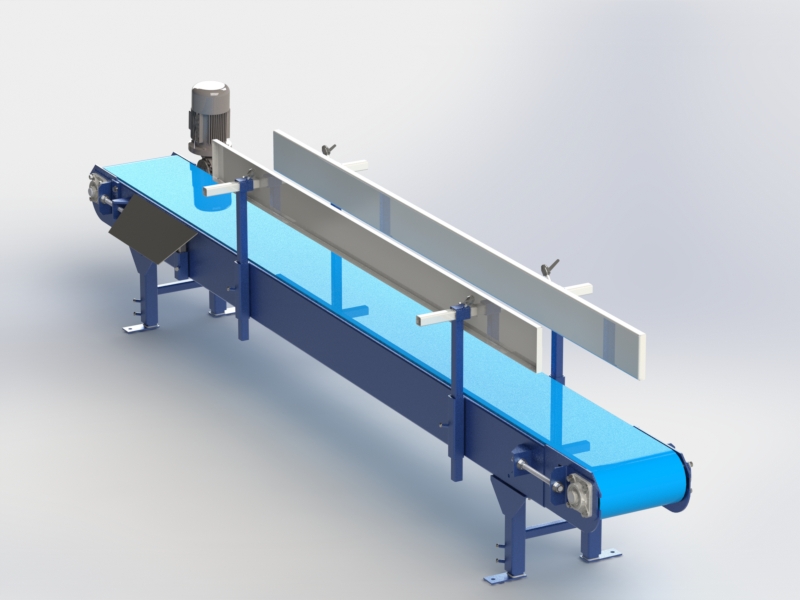

- Fully compatible with The Sack Filling Company’s range of conveyors systems.

Optional Extras

- Bag Top Trimmers: Stationary blade and rotary blade trimmer meets all application requirements

- Bag Trim Remover: Standard trim remover can remove up to 3″ or 5″ of trim

- Automatic Infeed: T Pak Infeed into Supersealer for high speed systems

- Conveyors: 6″ wide x 8′ long conveyors stocked, other conveyor sizes custom built

- Date/Lot Coders: Emboss coder and ink wheel coder provide up to 32 characters per line, both with up to two lines of code

- Bag Fillers: Scales, augers, robotics, and automatic bag loaders to create a seamless packing line

- Washdown and Corrosive Washdown: For wet and corrosive environments

- Deduster for Dusty Environments: Removes dust that creates barriers from seal area so that bag can be sealed