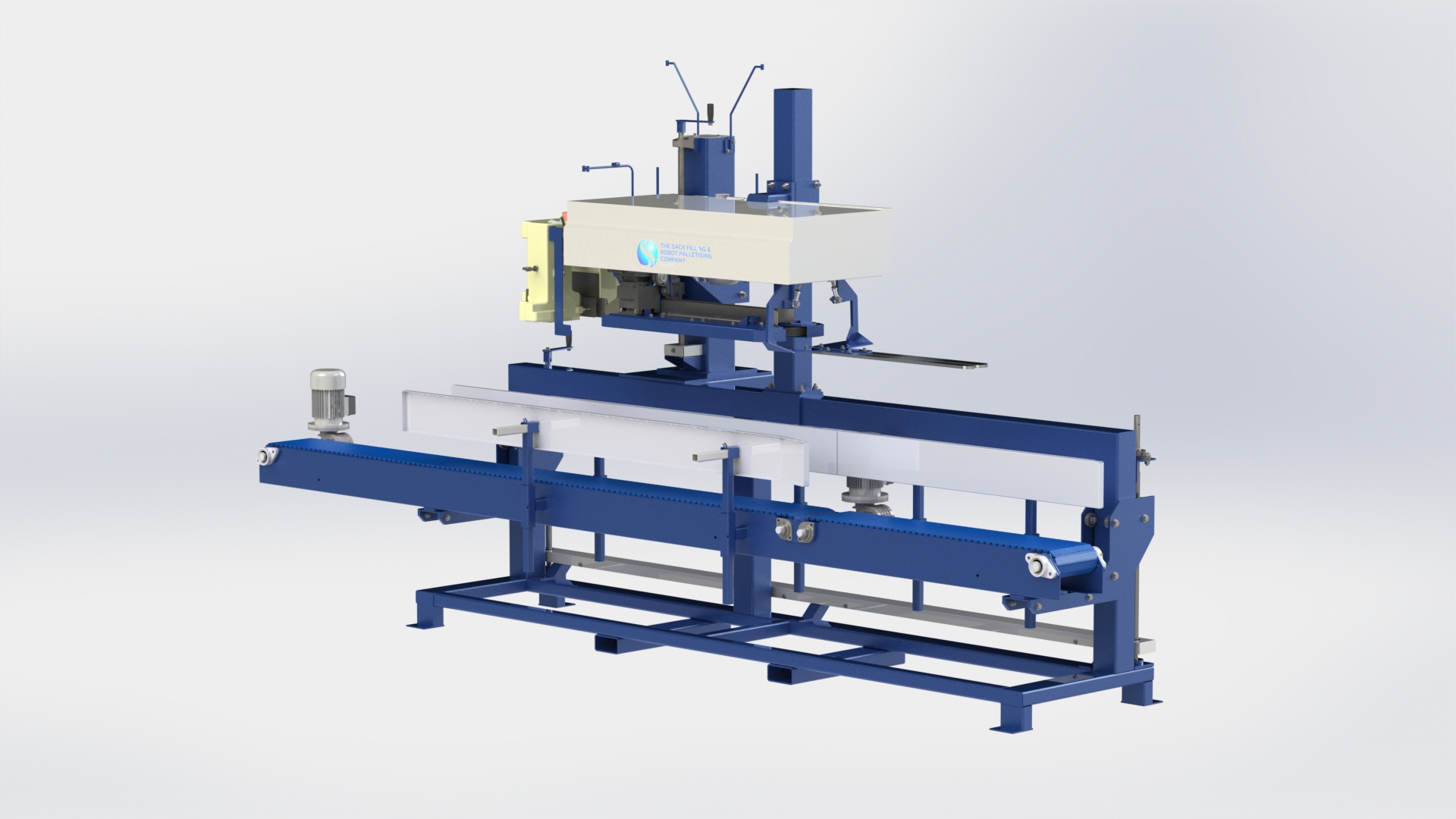

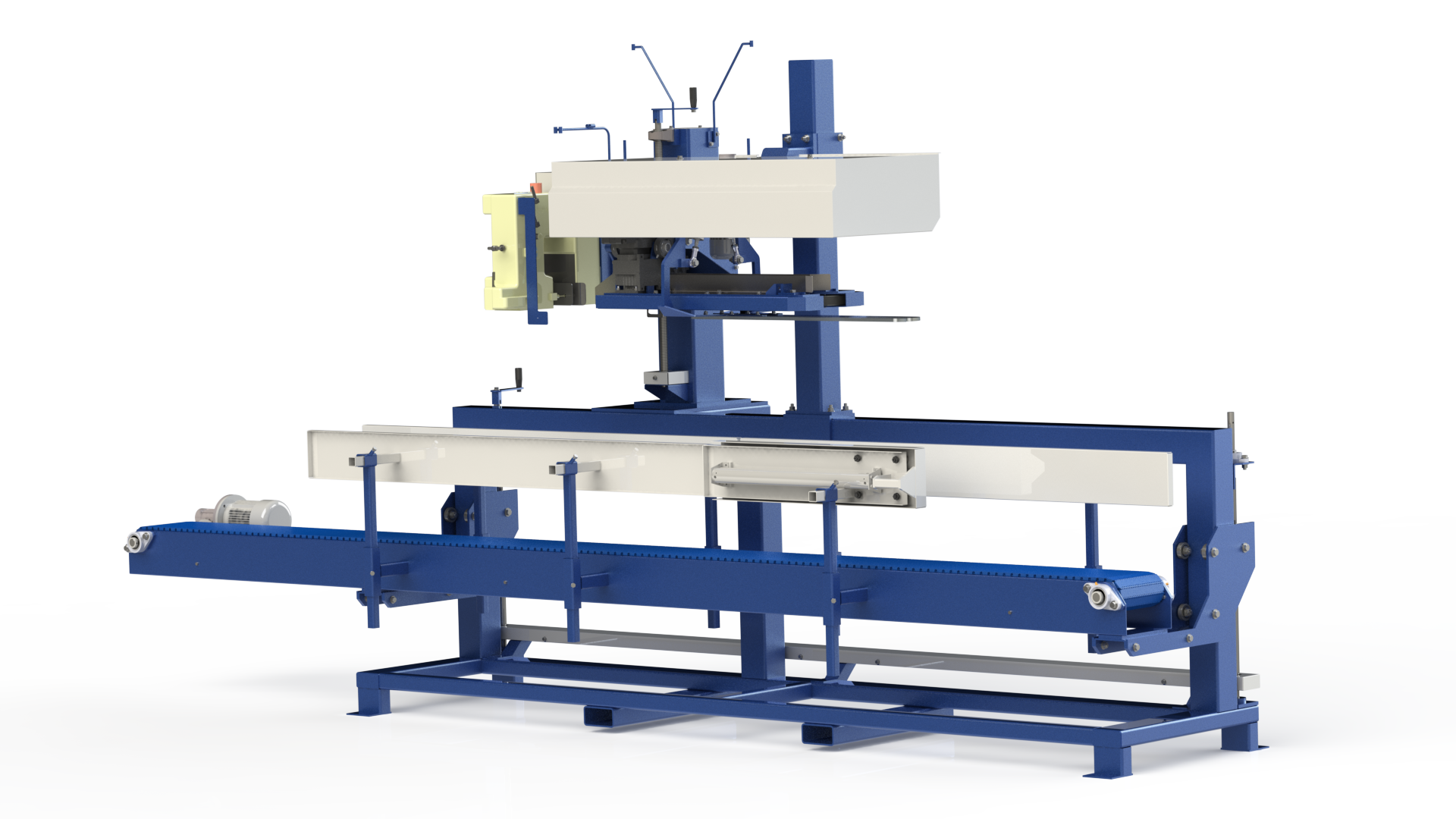

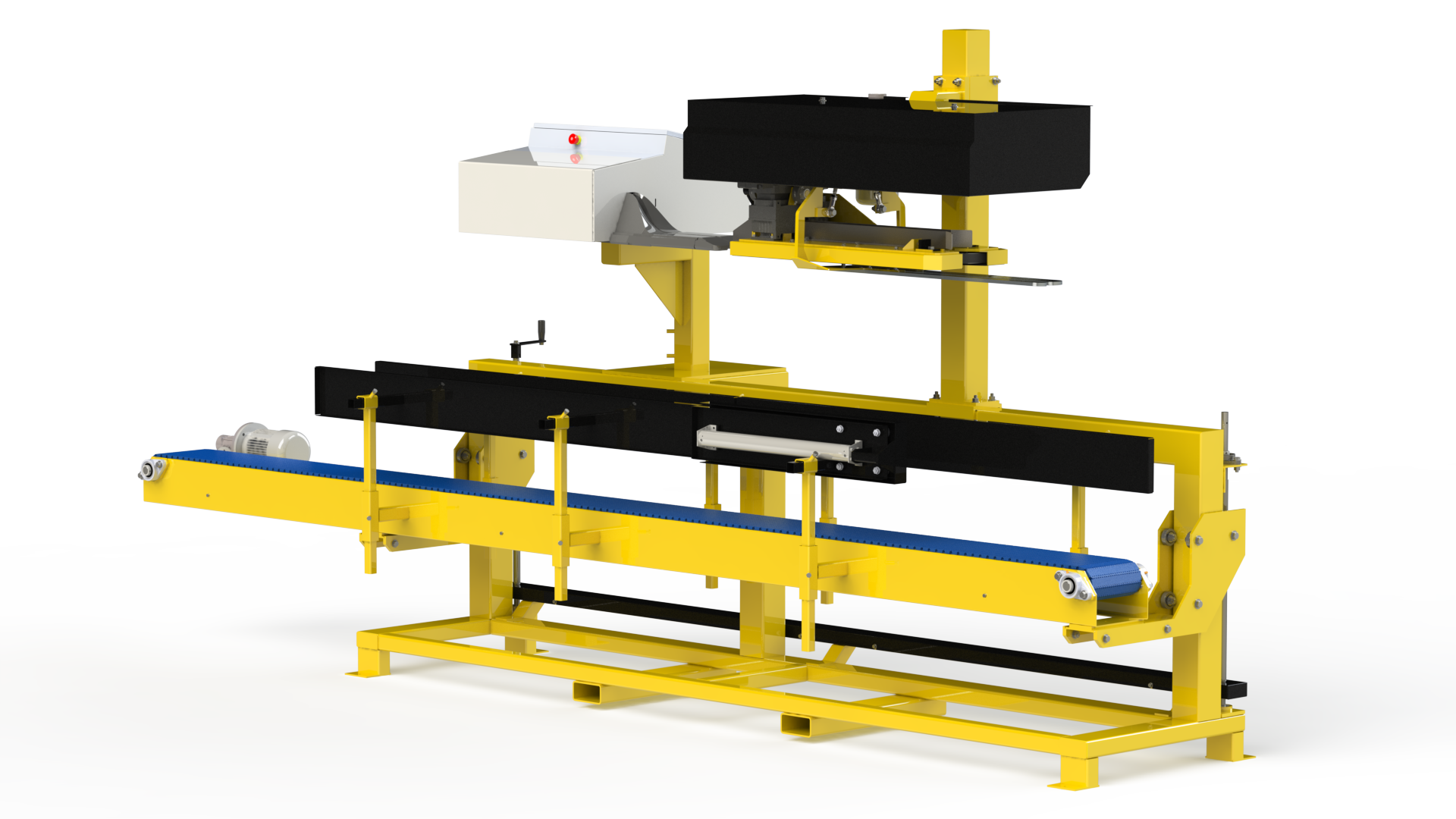

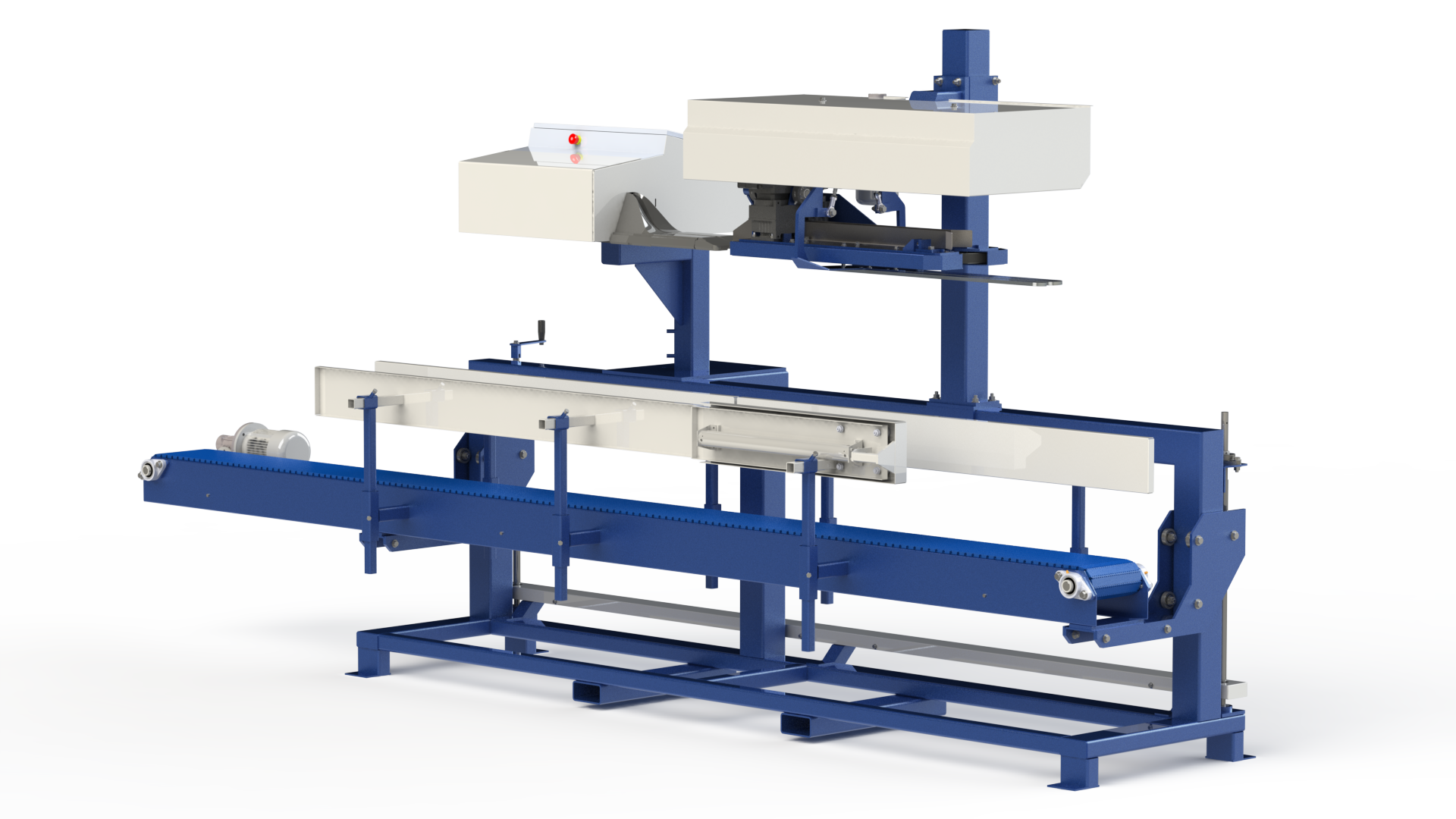

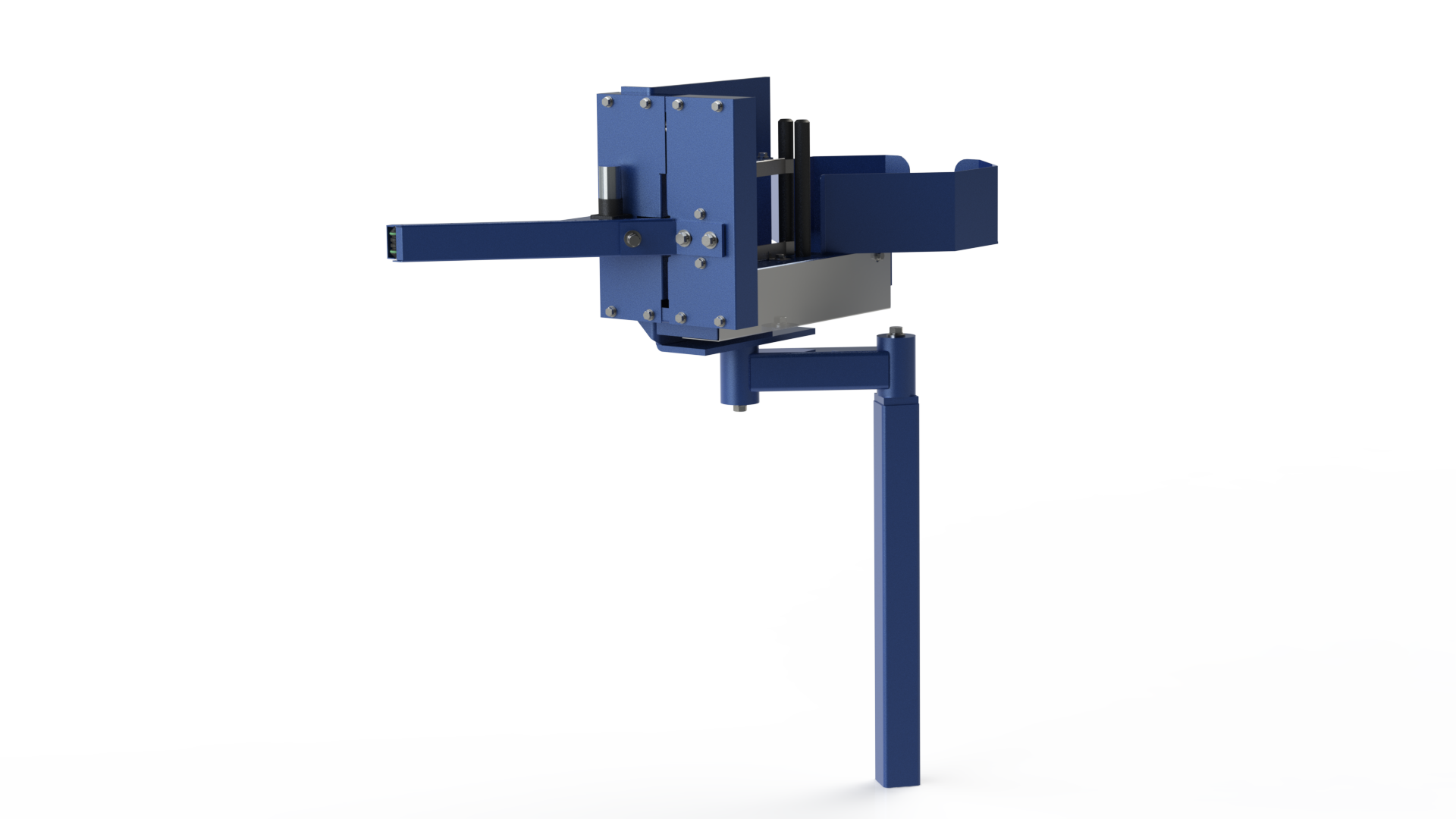

STC8900 High Speed Sack Top Control

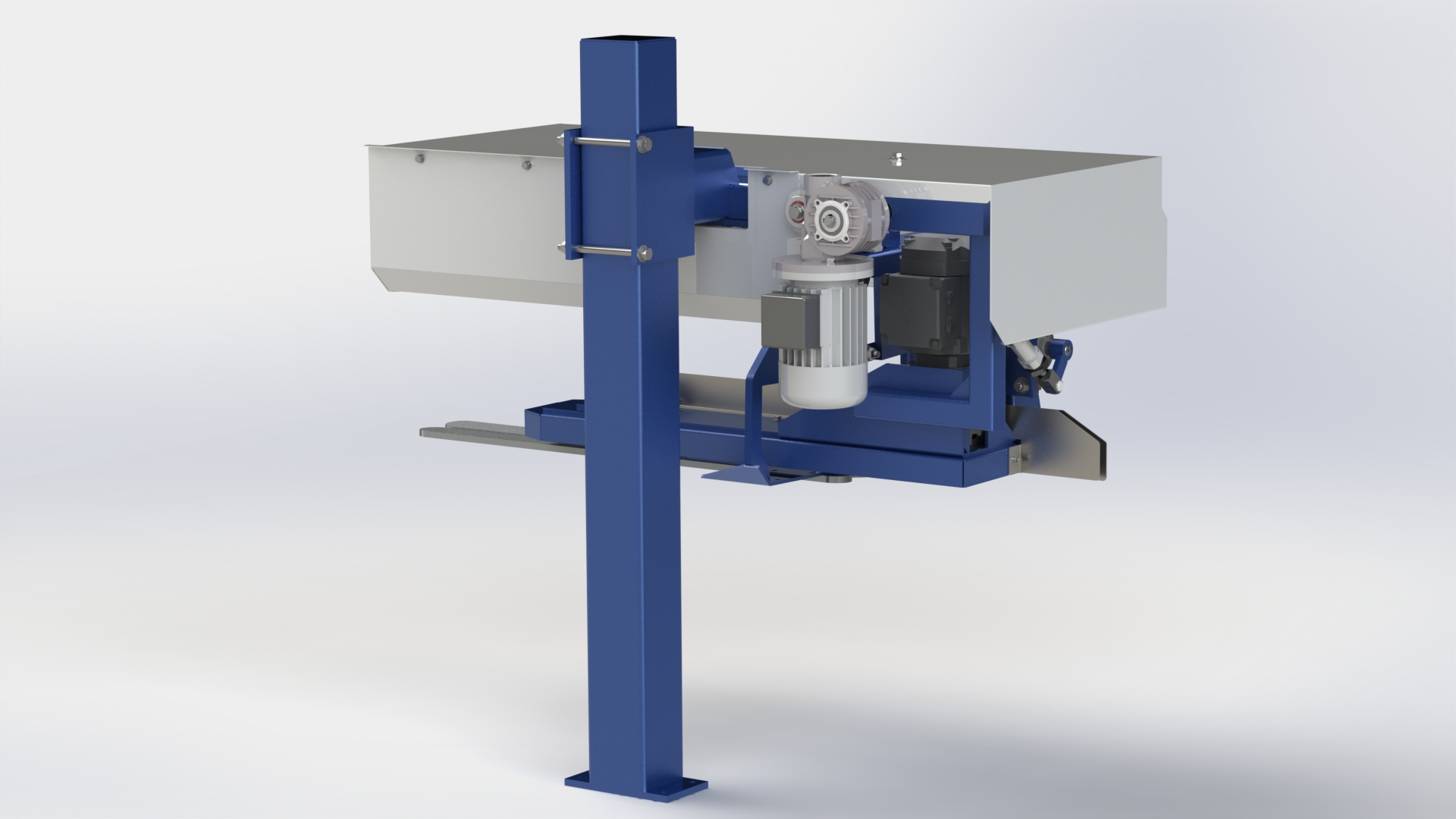

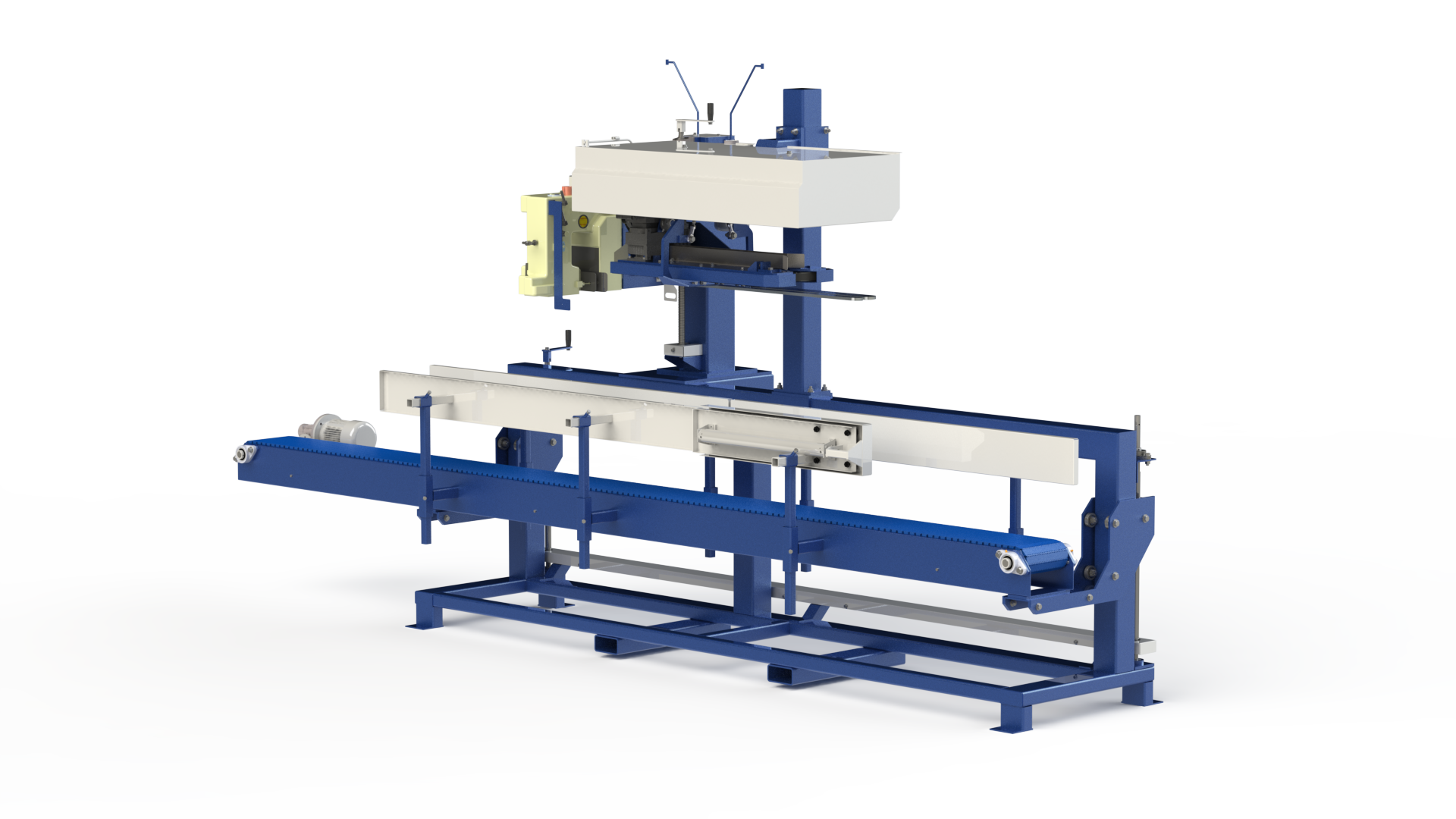

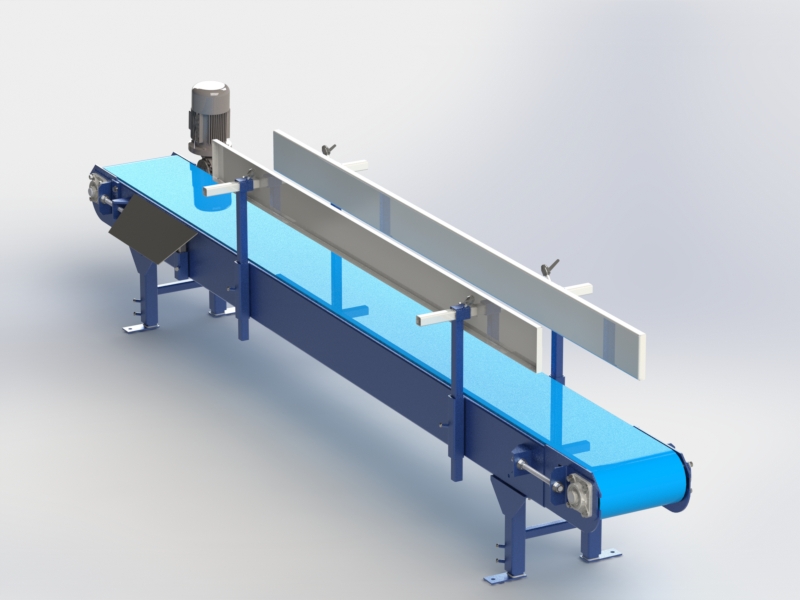

The Morray STC8900 incorporates a pneumatic bag clamp to hold the bag during the filling process. Once the bag is filled it is lowered onto an Intralox conveyor, at the same time two spreader fingers descend with the sack and spread the sack top. Two support arms then hold the sack top in the spread position and convey the filled sack forward to the stitcher or heat sealer before being released. The sack is supported at all times during this cycle to ensure an even, uniform seal every time.

Contact about this product

Key Benefits

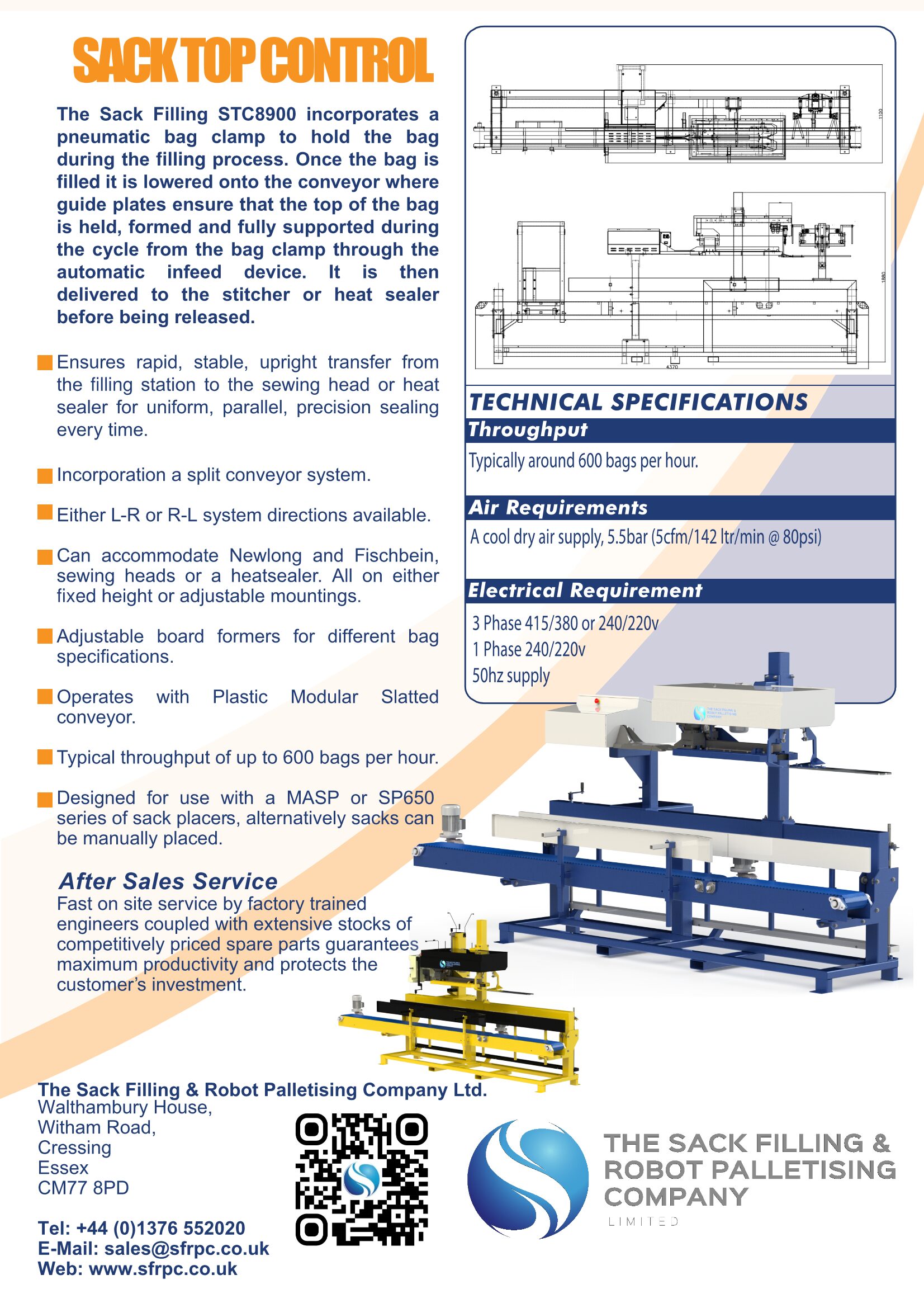

- Up to 12 bags per minute depending on material and bag type.

- Ensures rapid, stable, upright transfer from the filling station to the sewing head or heat sealer for uniform, parallel, precision sealing every time.

- Full pneumatic operation with PLC control for reliability.

- Can accommodate Newlong, Fischbein or another branded Heavy Duty sewing heads or a Heatsealer. All on either fixed height or adjustable mountings.

- Mounted above the conveyor on one robust chassis leaving floor area clear.

- Can be used with existing gross or net weighers.

Optional Extras

- Either L-R or R-L system directions available.

- Adjustable guide boards for different bag specifications.

- Plates available to mount other manufactured stitching heads, all mounted on either fixed height or adjustable mountings.

- Adjustable board formers for different bag specifications.

- Can be integrated with heat sealing or stitching system.

- Adjustable board formers for different bag specifications.

- Height adjusting conveyor.

– Electrical and manual height adjusting units. - Differing belt types for application: Slatted Modular Belting, Stainless Slat Band, Rubber Belting and Intralox® to meet the needs of your product.