With 35 years of experience in robotic applications The Sack Filling Company is ideally placed to apply a wealth of knowledge

and technical ability to almost any conceivable requirement.

Currently The Sack Filling Company offer the full range of Fuji-Ace robots from Fuji Yusoki Kogyo, which we consider to be the finest in the world for palletizing and de-palletizing applications. With superior reliability, speed, power efficiency, simplicity of operation and ease of teaching the Fuji-Ace is unparalleled in the palletizing marketplace.

Why Fuji-Ace from The Sack Filling Company?

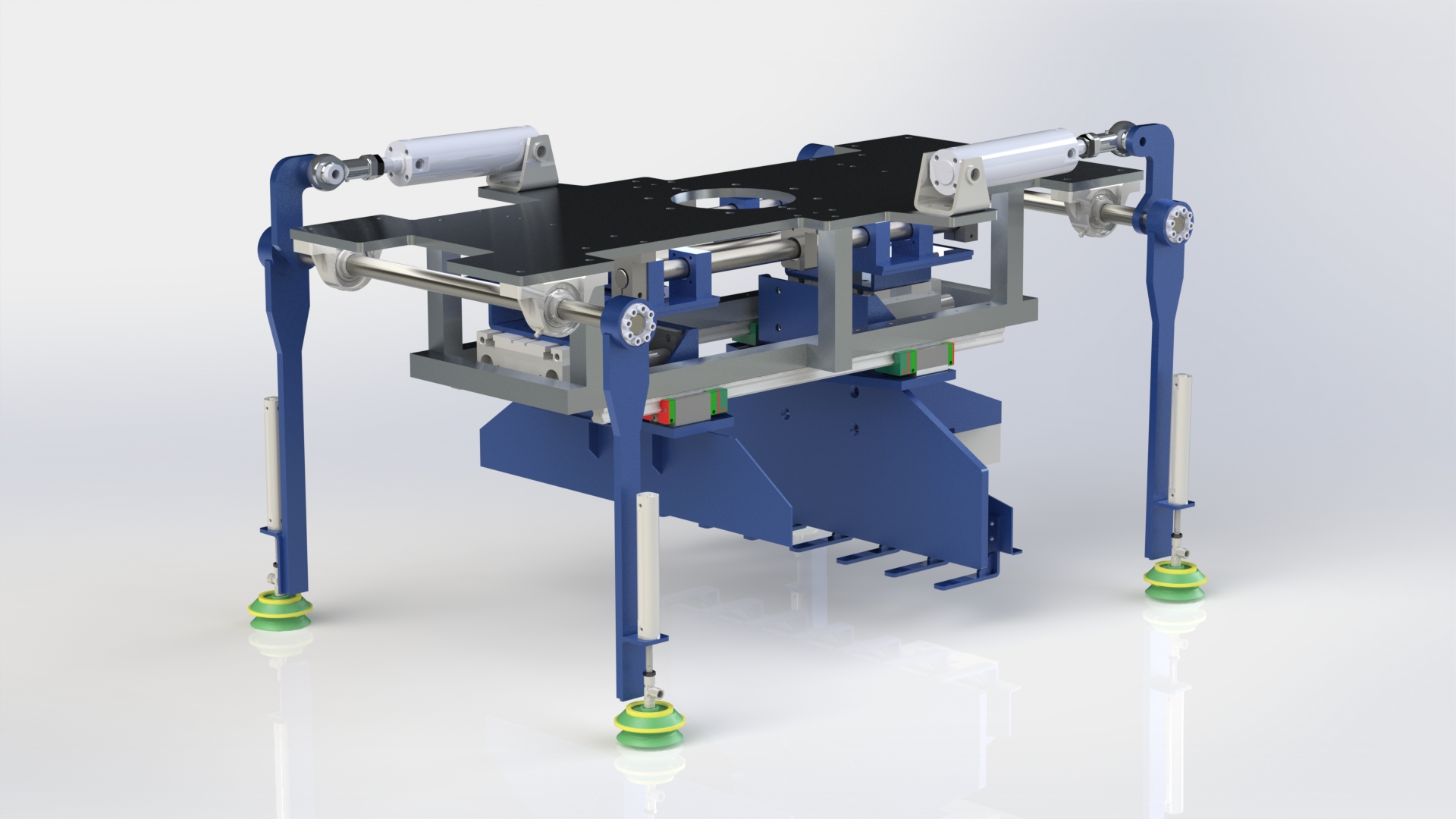

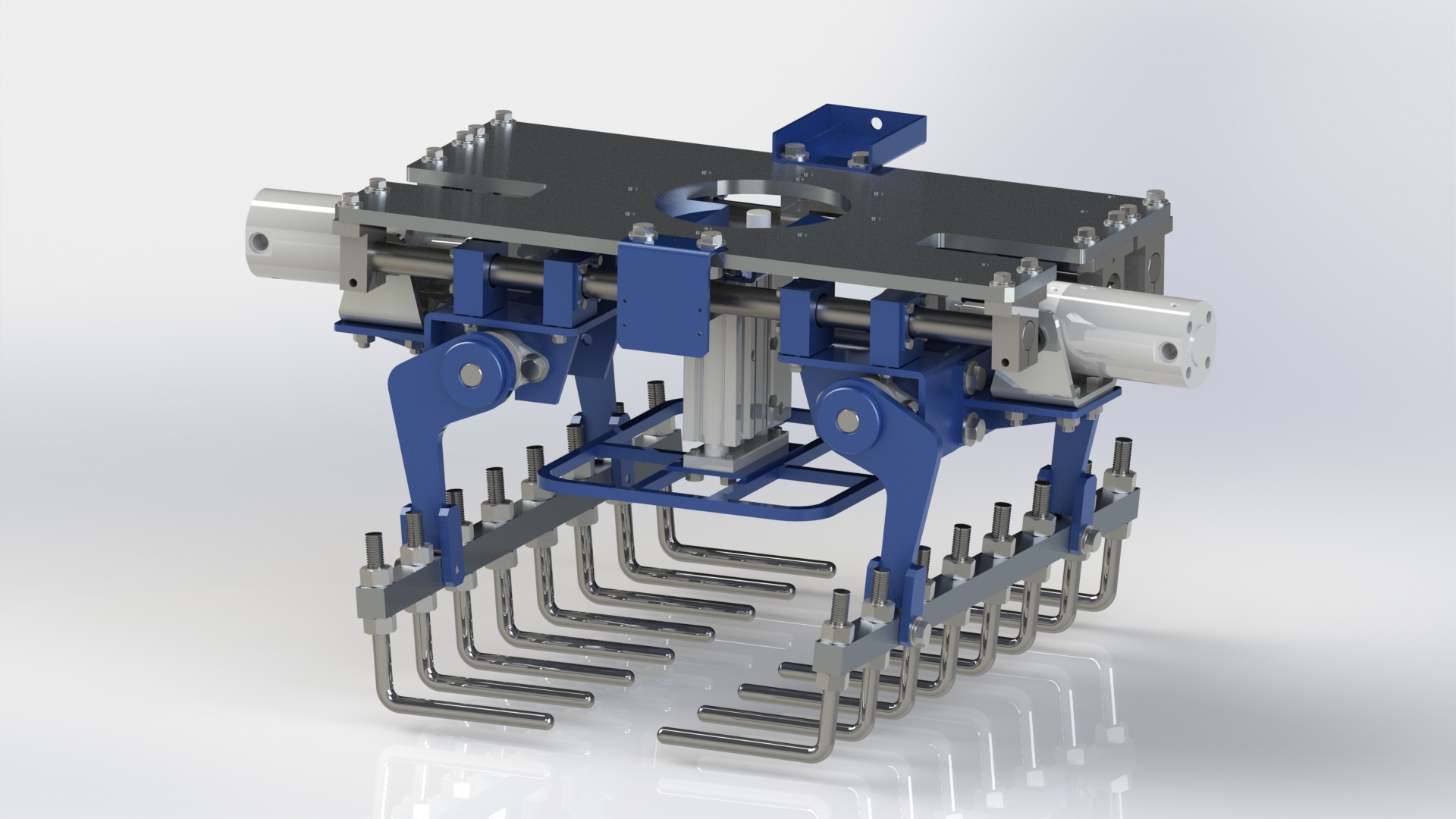

Unlike some other robot palletizers on the UK market, the Fuji-Ace was designed from the outset as a palletizing robot rather than a customised variant of a welding or general purpose industrial robotic unit. Because of this fact and the limited number of axis required to palletize versus tasks such as welding, Fuji Robotics were able to massively simplify and weight reduce the arm of their robots and use a far more efficient mechanical design for the actuation of the arm.

Power saving

Instead of using heavy, power hungry and complex cycloidal gearboxes with integrated servo motors specified by other manufacturers who integrate the actuation mechanism into their robot arms with the dead weight disadvantage this bring, all Fuji-Ace robots use external high efficiency servo motors with ball screws and timing belt drives.

This approach makes the robot simpler to service, parts are far cheaper in unit cost to replace and there is not surplus mass being carried by the robot arm. In fact Fuji takes this one stage further by making all Fuji-Ace arms out of high strength, low mass aerospace quality alloy thereby reducing the inertial mass of the system even further thus lowering the input power required.

Finally, by statistically balancing the arm with a counterweight, power is used only to move the load and not the arm itself.

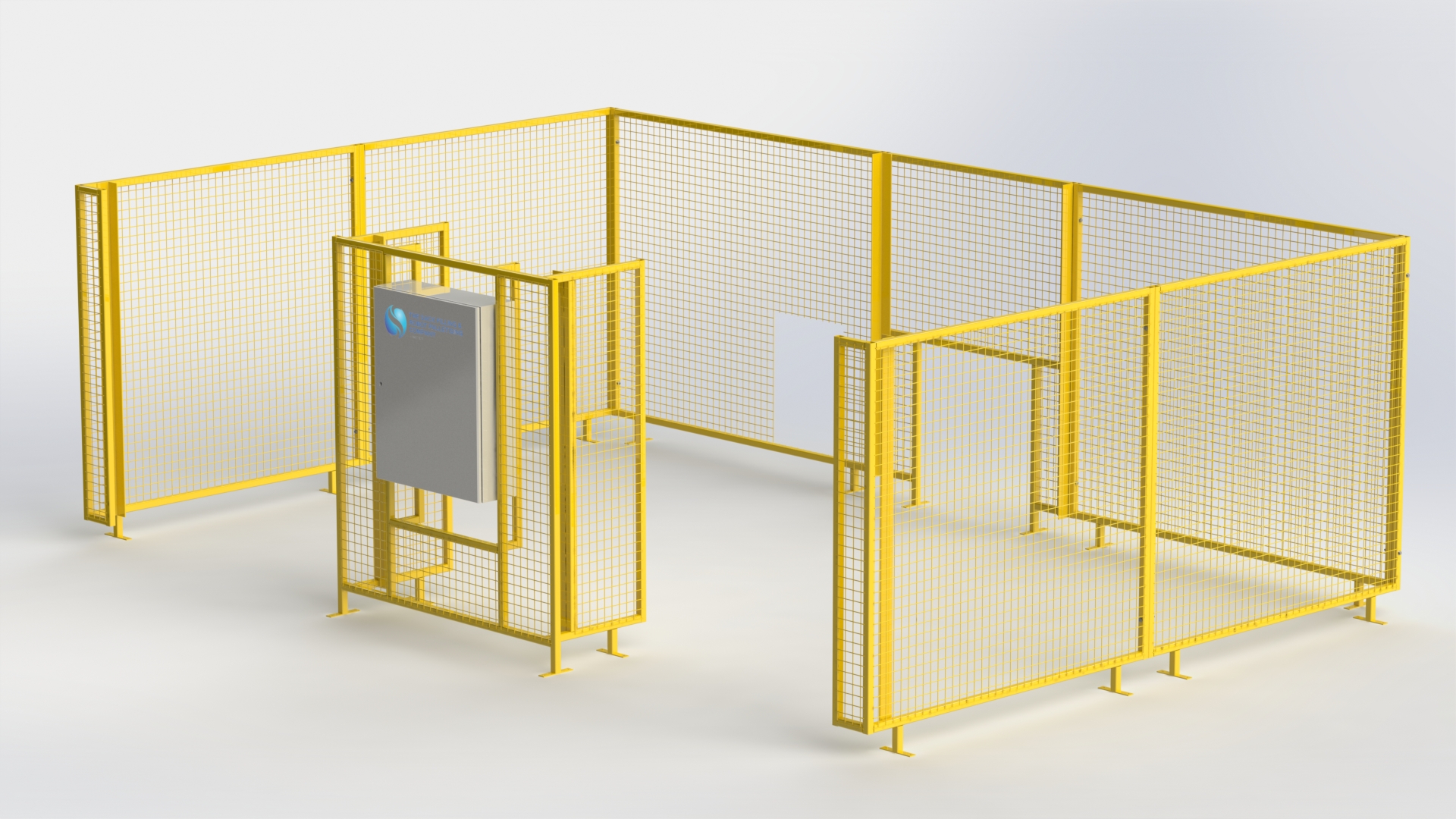

- Easy & Cost effective solution to meeting the Manual Handling Requirements.

- Optimized – no compromise design for palletizing

- Developed for high capacity production lines

- Simply integrated into existing plant layout

- System software can handle up to 4 varying product sizes onto 4 separate pallet positions – simultaneously.

- Speeds up to 1600 cycles per hour.

- Compact system footprint

- Depending on the product, the multi pick-up facility allows speeds up to 5000 units per hour.

- Up to 200kg lifting capacity.

- Touch screen programming panel.

- Ultra-quiet operation

- CE (UKCA) marked for use throughout Europe